Descriptions

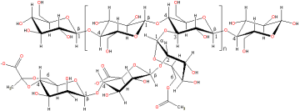

Structural Formula:

CAS No.:11138-66-2

Specifications:

| Viscosity 1% solution in 1% KCL | 1200-1600cps |

| PH 1% solution | 6.0-8.0 |

| Moisture | max 15% |

| Ash | max 16% |

| Assay | 91%-108% |

| Particle size | 100% through 60 mesh(250micron) min 95% through 80mesh(180micron) |

| V1/V2 | 1.02-1.45 |

| Shear ratio | min 6.5 |

| Pyruvic acid | min 1.5% |

| Heavy metal | max 20ppm |

| Lead | max 2ppm |

| Arsenic | max 3ppm |

| Nitrogen | max.1.5% |

| Microbiological | |

| Total plate count | not more than 2000 cfu/g |

| Yeast/mould | not more than 100 cfu/g |

| E.coli | absent/5g |

| Salmonella | absent/10g |

| Xanthomonas campestris | no viable cells in 1g |

| Ethanol and propan-2-ol | max.500ppm |

Applications:

as emulsifier, thickener, suspension agent and stabilization agent in food industry by controlling the rheological property, structure, appearance and flavor of the food products; as one of the main ingredients for cosmetics products due to its anti-oxidization and anti-aging properties stemming from its containing of many hydrophilic groups in its molecule; in the petroleum industry, due to its strong pseudoplasticity, a low concentration of xanthan gum (0.5%) aqueous solution can maintain the viscosity of drilling fluid and control its rheological properties, resulting in extremely low viscosity at high-speed rotating drill bits and saving power, besides, high viscosity is maintained in the relatively stationary drilling area to prevent wellbore collapse. And due to its excellent salt and heat resistance, Xanthan gum is widely used in drilling in special environments such as the ocean and high salt layers, and can be used as an oil recovery and displacement agent to reduce dead oil areas and improve oil recovery rates.

Packing: 25Kg/bag